Resortecs

Head of Communications & Branding, Davidson Leite

Textile recycling made easy. This is the promise that makes Resortecs one of the most exciting start-ups in the fashion industry today. Their innovations aim to change the way clothes are made, so that they can be more efficiently replaced, disassembled and processed into something new. This allows fashion producers to minimise their resource use and reduce their carbon emissions, while enabling recyclers to process more material at a higher quality.

Photography: Anouk Moerman & Damon de Backer

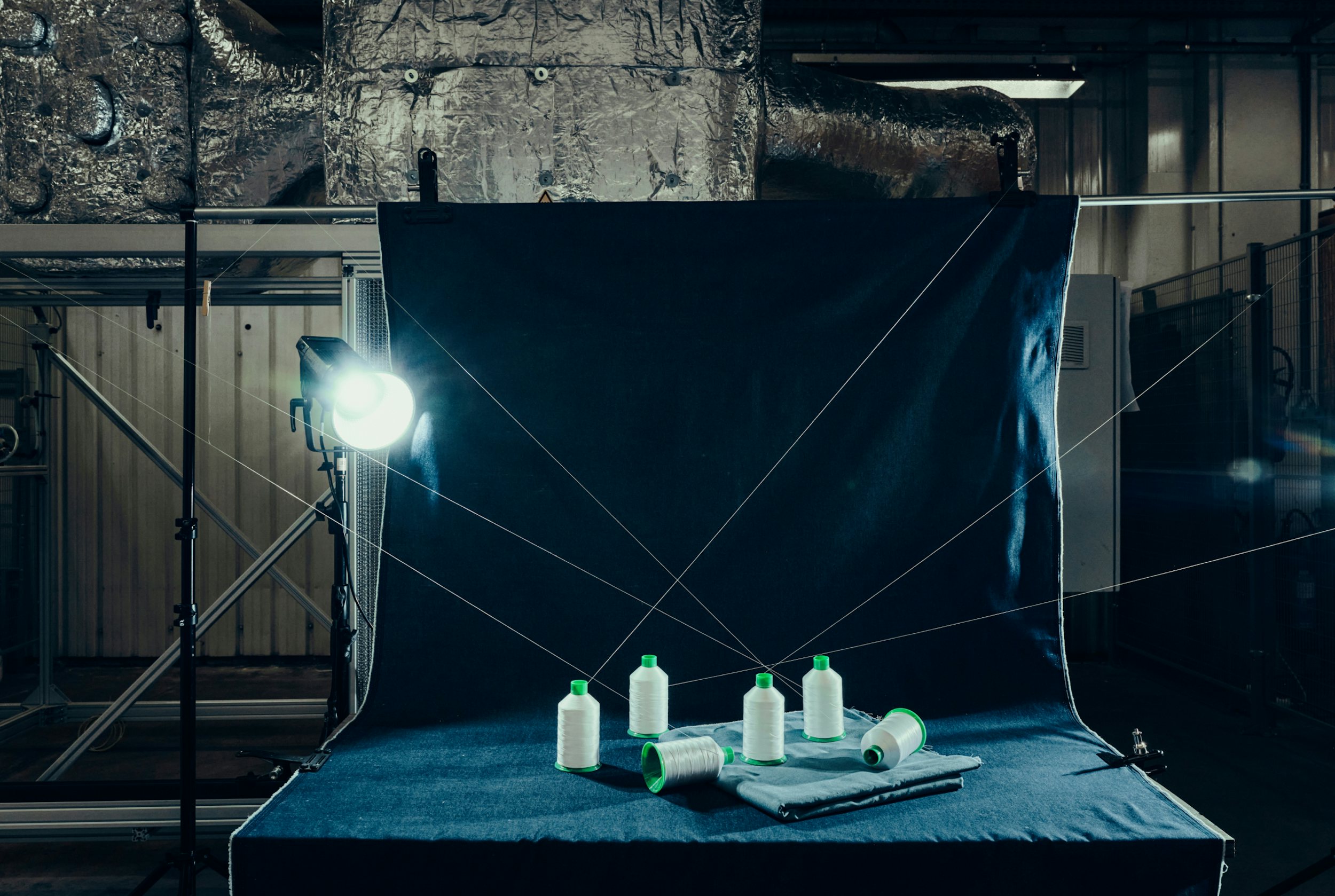

Resortecs’ thermal disassembly solution makes use of an innovative thread called Smart Stitch™ which dissolves under specific, high-heat conditions. This technology makes it possible for recyclers to disassemble and sort garments five times (!) faster than usual, without damaging the material or emitting much CO₂.

In a global industry like fashion, small changes like these can create a very big impact: according to Resortecs’ externally-reviewed Life Cycle Assessment, if all European-made garments were disassembled with their technology and efficiently recycled, the sector would generate 60.3 million fewer tons of CO₂ and save up to €2.3 billion per year.

Tell us the story behind Resortecs! How did it first come about?

Resortecs was founded in 2017 by Cédric Vanhoeck and Vanessa Counaert. Cédric studied industrial design and engineering before moving on to study fashion design at The Royal Academy of Fine Arts Antwerp after graduating. There he learned more about the fashion world and how much waste the industry produces.

Cédric realised that something had to be done to make fashion more circular. And I think that what really hit him was seeing that this was not being taught at schools and that most designers didn't have the tools to make things circular without compromising creativity or the usual industry standards.

He decided to drop out to found Resortecs with the idea of developing new technologies that would facilitate a more circular fashion industry. At first, he wasn't really sure of what he would do. But he knew that recycling is one of the most effective ways to reduce the environmental impact of clothing, and efficient recycling is not possible without design for disassembly. So: really thinking about the joining techniques and how everything in a garment could be made for being unmade.

Can you tell us a little bit about the industry you’re trying to change?

Well, we are working in fashion, which is one of the five most polluting industries in the world. I think that within the fashion industry there are multiple challenges. And there is no solution that is going to address all of those challenges. This includes everything from over-consumption to unethical working conditions and waste and recycling. The latter is what we've decided that we could do something about.

How is Resortecs doing things differently?

What we are doing is making recycling easy by eliminating the textile disassembly bottleneck: whenever you want to recycle a textile product, just like with your regular household waste, you need to separate things and send them to the correct recycling streams. But up until recently, this was super challenging because you only had two options.

The first option involved manual disassembly. By manual, I mean someone literally using scissors to pull every component of a garment apart. For a pair of jeans, for example, you’d have to remove the zippers, the waistband and all of the rivet buttons manually, which is so complicated and time-consuming that often companies just end up chopping it up. You can lose up to 52% of every pair of jeans you recycle this way. So this is obviously not efficient and not scalable.

The second option would be mechanical disassembly, which just means putting things in a huge shredder. Unfortunately, this mechanical process is not an option for many multimaterial or multilayer garments and very often shortens the fibres you’re working with. So what you can do afterwards is not really closed-loop recycling. You won’t get to make a new t-shirt out of an old one—you will only be able to downcycle things.

Thanks to our solution, you can now create a new T-shirt from an old one.

So Resortecs is working to make textile recycling more effective. Can you tell us about more your solution? What does it look like?

For a long time, the textile disassembly bottleneck would stop brands from even considering recycling. At Resortecs, we've developed a way to automate this process using components that dissolve with heat. What we offer to the industry are two complementary design-for-disassembly products: Smart Stitch™ and Smart Disassembly™. Fashion brands and garment makers use Smart Stitch™, which are heat-dissolvable threads, to create textile products designed for easy disassembly and recycling.

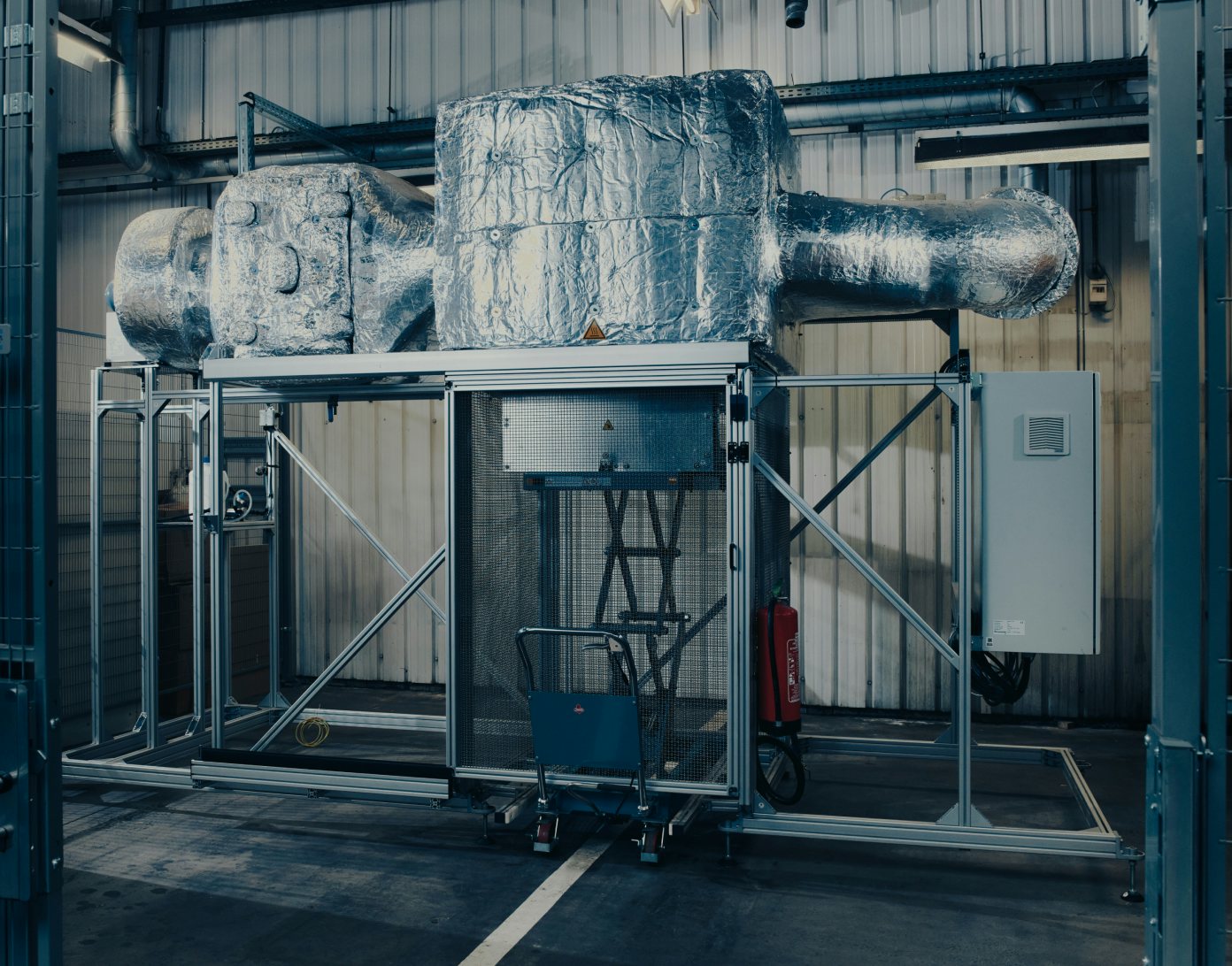

These threads look and perform just like regular threads, but they completely disappear at very high temperatures, automatically eliminating the seams and trims that block recycling. At the end of these products' lifecycle, sorters and recyclers turn to Smart Disassembly™, which are industrial thermal disassembly systems capable of dismantling tons of textile products without compromising the fabric's quality. By incorporating Smart Stitch™ during product manufacturing and Smart Disassembly™ at the end of a product's lifecycle, we can fully automate the textile disassembly process, reduce its costs, and make recycling easier for the entire fashion industry.

Your innovation improves the circularity of textiles. But making 100% sustainable choices is often difficult in practice. Have you had to make any hard decisions or trade-offs on other aspects of your product? How do you approach these dilemmas?

Well, one of the first things we had to consider was that some industrial processes involving heat can consume a lot of energy and usually damages the fabric parts of textile products. So how could we offer a solution that uses heat-dissolvable components and can process industrial volumes but is still sustainable and energy-efficient? In the end, our CTO and CSO worked together to ensure that our Smart Disassembly™ systems had a closed-loop heating mechanism, meaning that once you start it up, the heat keeps circulating inside. So you don't need to consume more energy to keep the process going—which is really important to reduce the carbon footprint of our disassembly process and keep our solution's environmental efficiency. And because there’s almost no oxygen inside our Smart Disassembly™ systems, the quality of the fabric is not affected by the high temperatures, as no oxidation is possible in such low levels of oxygen. In other words, the fabric won’t get damaged or burnt before the threads and trims have been eliminated.

Another thing we had to think about was the kinds of brands and partners we wanted to work with. Many people don’t understand why we’ve been primarily targeting fast-fashion or big brands. They ask: why work with a brand that has a bad reputation or is a big polluter? Well, those are the guys that we need to work with if we really want to change the industry. I think that this was maybe the most important trade-off we’ve had to make as a startup that is looking for funding but that is also really connected to its impact metrics, with very ambitious environmental targets.

What is the next step for Resortecs — and what do you need to get there?

Right now we are making the very expected, but also very difficult transition from the start-up to scale-up stage. Our team has grown a lot. When I joined two years ago, I was the third full-time employee, and now we are 17. So the growth is huge, huge, huge. And I think that right now is an exciting and also challenging moment, because we need to make sure that everything that I've been mentioning about impact, about the difficult decisions that we make and how we run the business, all stays the same. So really keeping the company's identity and purpose as we grow.

Another big challenge is that now is also the time to create an ecosystem, connecting sorters and recyclers, to ensure that the infrastructure for a circular future is in place when the entire industry makes the shift to a circular production model. We’ve been working hard to expand our influence towards policymakers, while pushing brands to go beyond the PR stunt or capsule collection approach. We are quite privileged, because we have worked with over 50 of the biggest names in the world of fashion. Everyone that has tested our solution knows it works, but many are still afraid of the lack of infrastructure for circularity. They're implementing our solutions too slowly. But I think that the recent legislation changes and our efforts to connect brands with sorters and recyclers is lighting a fire underneath their seats. They are feeling the heat, and they know it’s time to make a serious commitment to the circular economy.

Lastly, what is the main message you want to share with both producers and consumers alike?

That circular innovations are not happening in the future—these things are happening now. It’s very encouraging to see the diversity of smart and passionate people who are developing circular solutions today. I don't know if we can avoid a climate crisis, but I'm optimistic about how creatively and smartly we can manage and adapt to it.

I think the biggest power we have as individuals and consumers is to push brands in the direction we want. We can also reduce our consumption. So really reusing the things you already have, thinking three times before you buy something new. And when you finally buy something, do your homework. I think that brands are the ones who should be held responsible for making their products more sustainable and easier to disassemble and recycle, but I think that we, consumers, still can do our bit in researching the companies we buy from and understanding who is making the things you're wearing.

Of course, sustainable or circular options can sometimes be more expensive. So I understand that there's a notion of privilege there as well. But I think that educating yourself is the key. And for each person it might be a different solution. Is it going to be a matter of buying secondhand? Is it going to be repairing your clothes? Is it going to be washing them a little bit less so they last longer? Each person has the capability to understand their own context and make the best decision.

For designers, I think it’s just a matter of continuing to develop innovations and solutions. Collaboration is key, and the bigger the number of innovations that brands have at hand, the more governments see that these innovations already exist, the faster the circular transition will be.

More interviews

Secrid Talent Podium - ClimaFibre

Sunflowers can help to reduce our dependence and the environmental damage of cotton in the fashion industry.

Secrid Talent Podium - Super Local

Luc van Hoeckel designs solutions for the 90% of the world's population without access to decent basic facilities.

Secrid Talent Podium - Vorkoster

To combat food waste, Kimia Amir-Moazmi is working on a product that allows consumers to see for themselves whether food is still safe to eat.

Secrid Talent Podium - Solarix

Solarix designs and produces aesthetic solar panels as façade cladding.

Secrid Talent Podium - Claybens

Emy Bensdorp is developing a technique to transform clay soil contaminated by PFAS into 100% clean bricks.