Nuestro laboratorio de materiales

Trabajamos juntos para encontrar los mejores materiales

Presionamos, golpeamos, rasgamos, maltratamos y sometemos a nuestros materiales a todo tipo de abusos. Los pocos que componen la cartera que lleva en el bolsillo sobrevivieron a la paliza como es evidente. Pero ¿cómo? ¿Y por qué surgieron como las opciones más viables en primer lugar? Al igual que en la vida real, donde no todo es blanco o negro, a veces hay que tomar decisiones difíciles. Esto ocurre en nuestro Laboratorio de Materiales.

La primera criba en el Laboratorio de Materiales

En el Laboratorio de Materiales, no siempre llevamos batas blancas y gafas de seguridad. En realidad, el laboratorio funciona como un espacio de colaboración, tanto entre colegas como con socios externos, como empresas emergentes que desarrollan nuevos materiales. Este trabajo implica la realización de pruebas físicas en los materiales, pero también incluye su exploración y evaluación a través de métodos de investigación alternativos.

Para que un material se incluya en la lista de posibles materiales, se somete a un examen exhaustivo. Vendría a ser como una extensa verificación de antecedentes durante una solicitud de empleo. ¿Se fabrica respetando el planeta y en buenas condiciones de trabajo? ¿Tiene el proveedor las certificaciones adecuadas? ¿Qué hay de la distancia de transporte? ¿Es lo suficientemente local como para garantizar una huella de carbono baja?

La lista continúa y, a estas alturas, ya nos hemos dejado los sesos en la primera criba de nuestra investigación de materiales. Para que se haga una idea, en un momento dado podemos tener más de 50 materiales catalogados como «potenciales futuros».

A prueba

Después de examinar al proveedor de materiales y de inspeccionar el propio material, es el momento de ponerse las gafas de seguridad y probarlo físicamente. Lo rasgamos, doblamos y frotamos, en algunos casos, decenas de miles de veces. Con máquinas con nombres ilustres como flexómetro y crockmaster, que parece una máquina de pulir zapatos que nunca se detiene: probamos el grosor, la abrasión, la flexión y la resistencia al desgarro, la solidez del color y el deshilachado.

Estas pruebas se realizan de acuerdo con las normas ISO, de modo que son repetibles y proporcionan un valor predictivo. Pero para nuestros accesorios de bolsillo, incluso construimos nuestras propias máquinas personalizadas para probar los materiales de distintas formas, como simular, por ejemplo, cómo se comportan al caer sobre un suelo de hormigón. Otra máquina nos permite tirar de la palanca de un Cardprotector literalmente más de un millón de veces para comprobar si el material del resorte interno sobrevive.

A pesar de toda la estandarización, las pruebas en el Laboratorio de Materiales pueden seguir siendo sorprendentes. De vez en cuando, nos topamos con resultados que no esperábamos: ¿por qué el resultado de la prueba dista tanto del anterior? A veces, parece como buscar una aguja en un pajar, lo que puede ser bastante difícil. Por suerte, hay veces que el problema es tan simple como un envío de material equivocado por parte del proveedor. Sea como sea, estas sorpresas nos mantienen alerta.

Panorama general

El maltrato físico de los materiales sirve para garantizar su resistencia y durabilidad. Nuestro objetivo es que nuestros accesorios de bolsillo tengan la mayor vida útil posible, para que nuestros clientes desarrollen una conexión duradera con nuestras carteras.

Sin embargo, la longevidad no solo se reduce a la durabilidad; también implica un diseño atemporal y una experiencia táctil que hace que el uso diario sea placentero. Dicho de otro modo, los clientes suelen sustituir los productos cuando dejan de resultar atractivos. Esto es algo que intentamos evitar en la medida de lo posible.

Tomemos el caso del cuero, por ejemplo. Al ser un material natural, envejece con el uso. Aunque muchos tipos de cuero son duraderos, no todos envejecen bien. ¿Sigue teniendo su cartera un aspecto atractivo después de años de uso?

Este ejemplo ilustra cómo las discusiones sobre la prolongación de la vida útil se relacionan con nuestro punto anterior acerca de la complejidad de la investigación de materiales. A menudo no está claro cuál es la mejor opción inicialmente. Por lo tanto, nos esforzamos por enfocar la investigación de materiales de manera holística: realizamos evaluaciones en función de los resultados. No descartamos opciones de antemano, lo que suele conducir a decisiones difíciles.

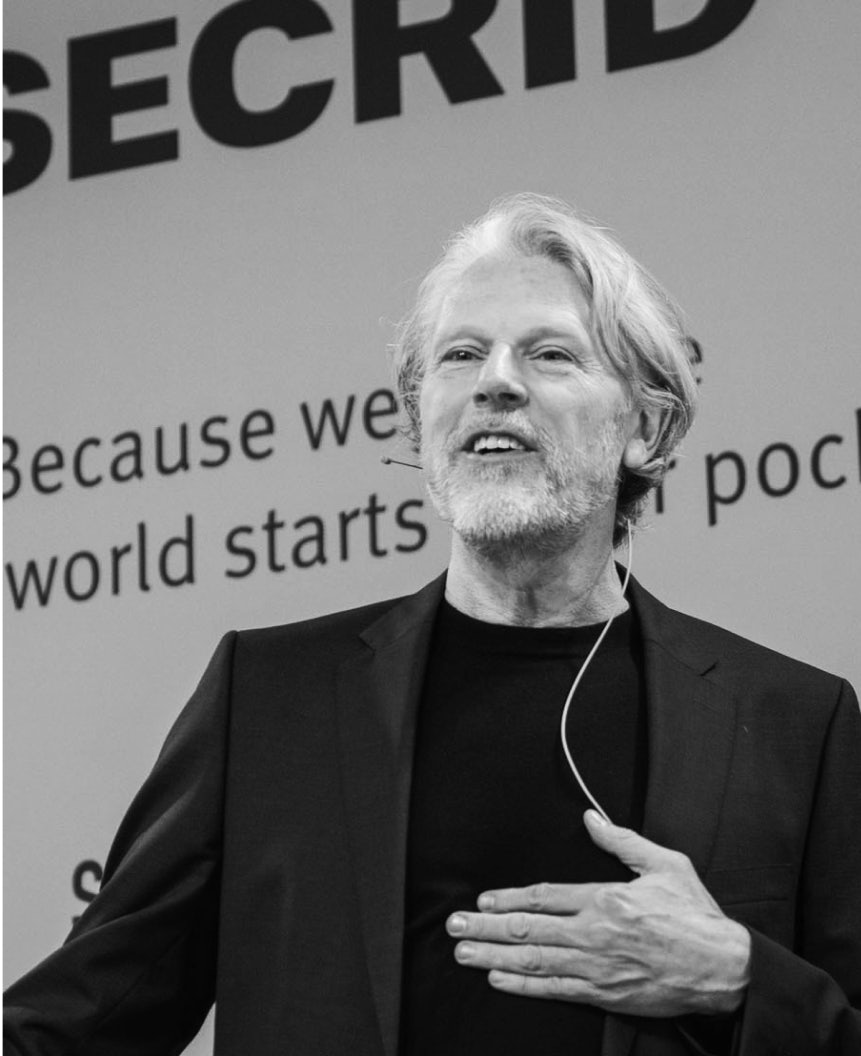

«El mundo rebosa innovación, con nuevos materiales que surgen todo el tiempo, ¡y nosotros también los tenemos en cuenta! Muchos parecen interesantes y prometedores. Pero ¿qué materiales son realmente mejores, más sostenibles y valiosos? Nuestro Laboratorio de Materiales se dedica a responder a esta pregunta».

Thomas Beekhuis, Sostenibilidad

¿Plástico fantástico?

El plástico es un buen ejemplo de elección controvertida. La creciente cantidad de residuos plásticos es preocupante, y los plásticos están hechos a base de fósiles, lo que los hace intrínsecamente problemáticos. Al mismo tiempo, es un dilema porque, si se aplican correctamente en productos que duran mucho tiempo, pueden desempeñar un papel importante en la prolongación de la vida útil del producto. Por lo tanto, el plástico también puede ralentizar la tasa de generación de residuos.

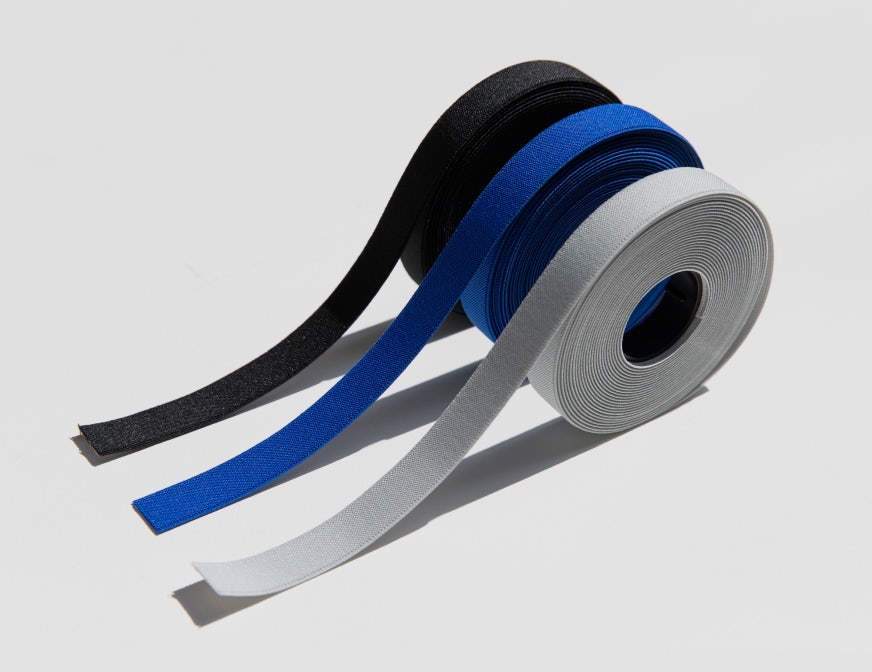

Sopesamos cuidadosamente los pros y los contras y estimamos que el plástico virgen (no reciclado) tenía un buen potencial, así que lo probamos. Valió la pena: después de dos años de probar varios plásticos, descubrimos que el TPU (poliuretano termoplástico) es en realidad un material muy adecuado para nuestros accesorios de bolsillo.

El TPU es muy duradero, fuerte y resistente a los arañazos, lo que lo hace ideal para aplicaciones resistentes pero flexibles. Aunque algunos plásticos reciclados, como el PVC, también ofrecen durabilidad, a menudo dependen de aditivos que liberan gases nocivos. Por el contrario, la producción de TPU implica menos productos químicos tóxicos.

Además, el reciclaje de PVC es complejo debido a estos aditivos, mientras que el TPU funciona bien en el reciclaje mecánico, ya que produce artículos reciclados de mayor calidad. En definitiva, el plástico virgen en forma de TPU era la opción más limpia y sostenible para nosotros.

Dilemas en el Laboratorio de Materiales

La mayor parte de nuestro trabajo en el Laboratorio de Materiales se centra en alternativas al cuero, ya que nuestra empresa está comprometida con el bienestar animal y el vegetarianismo. Secrid tiene como objetivo reducir significativamente el consumo mundial de productos de origen animal. Sin embargo, seguimos utilizando cuero para la mayoría de nuestros accesorios de bolsillo.

¿Por qué no dejar de usar cuero para nuestros accesorios de bolsillo? Por desgracia, no es tan sencillo. Esta pregunta nos planteó un dilema: tanto el cuero como las alternativas al cuero tienen ventajas e inconvenientes. Abordamos este dilema pensando en sus consecuencias.

Así que sí, las alternativas al cuero generalmente no tienen una influencia negativa directa en el bienestar animal. Y las alternativas al cuero están mejorando rápidamente. Sin embargo, el cuero sigue siendo inigualable en cuanto a durabilidad y, como se ha mencionado, envejece estupendamente. Además, las alternativas al cuero a menudo plantean sus propios desafíos medioambientales debido, por ejemplo, a recubrimientos o fibras plásticas perjudiciales para el medioambiente.

Consideramos que las pieles de vaca son un producto de desecho de la industria cárnica y láctea. Mientras la demanda mundial de carne y productos lácteos supere la de cuero bovino, estas pieles podrán suprarreciclarse para fabricar artículos de cuero de alta calidad. En esencia, podemos producir cuero que sea más respetuoso con el medioambiente y duradero que muchas alternativas de cuero actuales.

El futuro material

Estamos entusiasmados con el futuro en el Laboratorio de Materiales. A nivel mundial, existe una creciente concienciación sobre la importancia de la investigación de materiales y su impacto en las personas y el medioambiente. Se están llevando a cabo fascinantes avances para reducir los flujos de residuos, como la producción de una alternativa al cuero a partir de huesos de aceituna.

Nosotros también estamos reduciendo los residuos mediante el reciclaje de los Cardprotectors dañados mediante recubrimiento en polvo o «martilleo». Esto no solo minimiza los residuos, sino que también da como resultado materiales de superficie únicos con texturas distintas.

Conocemos nuevos materiales de diversas maneras. Una forma de hacerlo es a través de Secrid Impact Fund: apoyamos Celium™ de Polybion, uno de los ganadores del desafío What Design Can Do de 2024. Celium™ es un material vegano y orgánico producido por bacterias alimentadas con residuos de frutas agroindustriales. Junto con Polybion, estamos probando y trabajando continuamente para que este material cumpla con los estándares de la industria.

En Secrid, llevamos investigando y probando materiales desde el inicio. Nuestro Laboratorio de Materiales se ha creado para abordar este tema de una manera estructurada y holística. Finalmente, este trabajo da como resultado los accesorios de bolsillo Secrid que lleva consigo. Esto hace que la investigación de materiales sea aún más gratificante ahora y en el futuro.

Historias cortas

La magia de los detalles

Es la hora de almorzar. Debido a corona, René, el cofundador de Secrid, no está hoy en la oficina con su equipo, sino en el salón con sus padres, ya, Gerrie (81) y Joop van Geer (91). Hablamos a través de Teams acerca de la relación padre e hijo y de cómo Joop inspiró a René, y también hablamos sobre el diseño del resorte de las carteras.

Fabricamos tu cartera

Secrid lleva un negocio próspero y que intenta desempeñar el papel que le corresponde en la sociedad: crear empleo, respetar a las personas y al planeta y fabricar productos de calidad para su uso diario.

La búsqueda de materiales duraberos

La Bandwallet de TPU es innovadora y duradera, inspirada en ropa de trabajo y diseñada con una soldadura fuerte e impecable. La funcionalidad y la estética se funden literalmente en la nueva Bandwallet de TPU.

¡Conoce a la comunidad Secrid!

Siempre estoy en Babia y soy de lo más caótica; así que siempre perdía las tarjetas. El Cardprotector fue el regalo perfecto para mantener mis tarjetas a salvo.

La Evolución Industrial

En lugar de productos “más baratos y de peor calidad”, los productos nuevos deberán ser intrínsecamente “mejores, más sostenibles y más valiosos”.

Secrid es una empresa B

Mientras que son muchas las empresas que solo se centran en obtener beneficios a toda costa, las Empresas B tienen en cuenta, sobre todo, los efectos para las personas, la naturaleza y el planeta.