Claybens

Emy Bensdorp

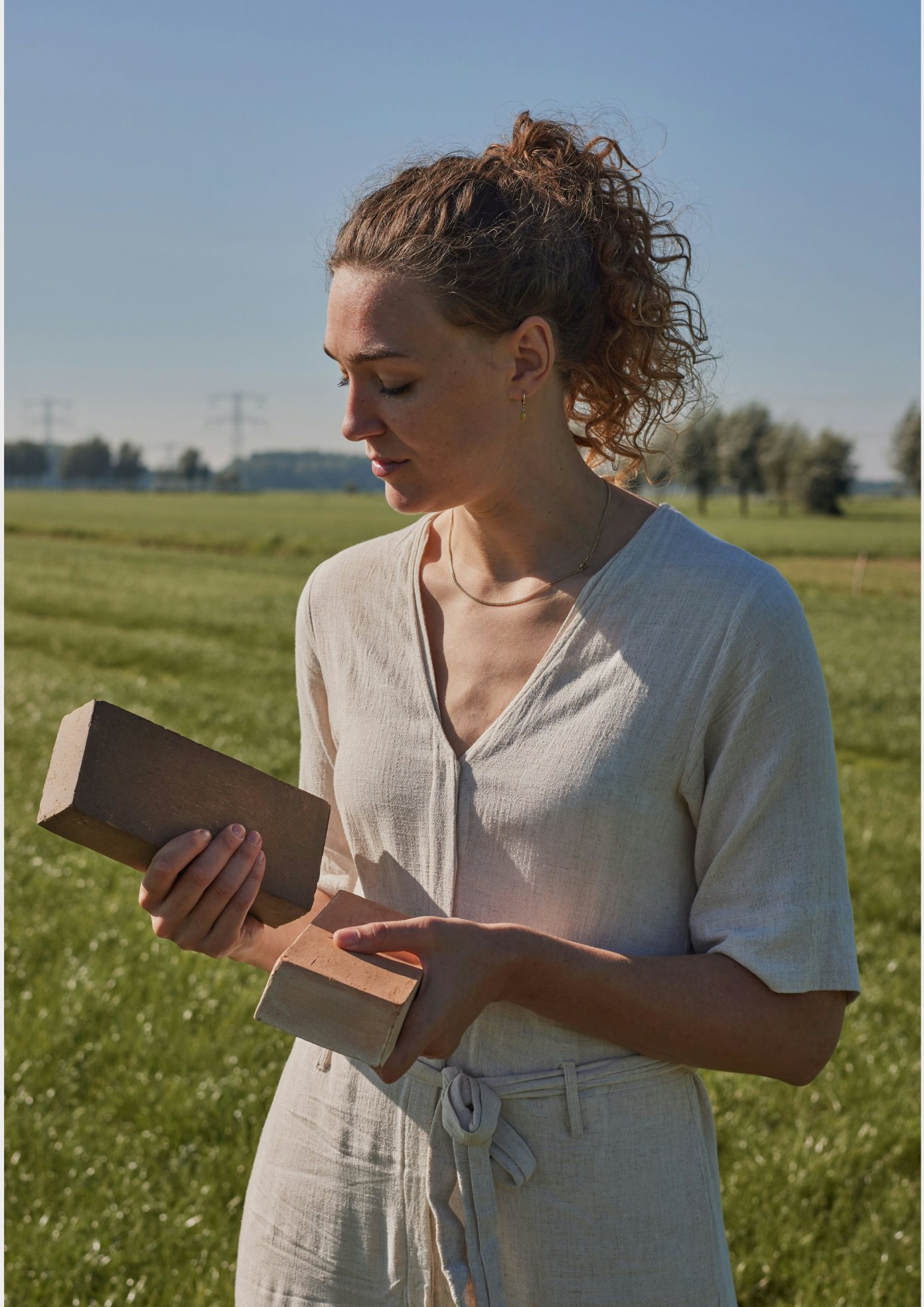

Emy Bensdorp is developing a technique to transform clay soil contaminated by PFAS into 100% clean bricks. The heat of the baking process breaks down the toxic chemicals to create a product that can be widely used to build our homes. An answer to a tricky challenge that until now did not have a solution.

PFAS are man-made chemicals that have been used since the 1950s. These substances are used in a huge array of products because they are water, grease, and dirt repellent, but the toxic and non-degradable production waste ends up in our natural environment and food chains. Neither government nor companies have so far come up with a suitable solution for this problem.

We spoke to Emy about the PFAS problem and how she came to turn contaminated clay soil into bricks, which she now wants to bring to the market.

Photography: Anouk Moerman

Film: Blickfänger

Hi Emy, would you like to share with us what drives you and how you see your role in this world?

I am a naturally curious person and love to dive deep into issues I care about. To connect various things together, to try and make the world more beautiful and sustainable. I like the Planet Earth series with all those natural systems that are perfectly attuned to each other, but also how we as humans just stomp all over them. Humans throw things out of balance, as a designer I try to find creative solutions that address the problems we’ve created. After studying Psychology, I discovered that this is the purpose of design. This appealed to me so much that I then attended the Design Academy Eindhoven.

You want to fix something that people have broken. Can you tell us about the specific problem where you want to make a difference?

In 2019, PFAS was in the news a lot. It turned out to be in everything and it could make you very sick. PFAS are man-made chemicals that have been in use since the 1950s. They are used in both industrial and consumer products ranging from waterproof clothing and frying pans to fire-fighting foam.

I understood that humans had introduced this substance into the world for a reason. These fabrics do their job extremely well: they’re heat-resistant, water-repellent, and last a very long time. A bit too long in fact, namely thousands of years. We’ve never given thought to what happens to those substances when we throw the product away. Over the years they have ended up in our environment. PFAS chemicals are very resilient and do not break down naturally. And now they‘re everywhere in our water and soils. We can no longer get rid of them, and it turns out they are extremely harmful to the environment as well as to our health.

We want to bake 50,000 bricks for a terraced house.

So, you realized that there are toxic PFAS substances almost everywhere around us. What did you come up with as a solution?

When I heard about the PFAS problem, I started researching, and clay soil caught my attention. This type of soil cannot be washed like sandy soil, and due to its density, it retains large amounts of PFAS. That was the start of my design process, after which I started collecting information until everything fell into place.

During my work as a designer, I gained some experience with ceramics. Making ceramics entails baking clay at 1000 degrees in a special oven, so when I read that PFAS chemicals are rendered harmless around these temperatures, the penny dropped.

By heating PFAS-contaminated clay soil at high temperatures you break the c-f bond of the chemicals making them harmless, and simultaneously you can bake a brick.

There is so much PFAS captured in clay soils globally and my goal is to eliminate those chemicals completely.

Can you tell us about the industry you entered at that time? What does the construction world look like?

After developing the product, I started to delve deeper into the brick industry. I wanted to know what the mass production of bricks looked like so I could fit my product into that system. The brick industry is a beautiful traditional industry, where craftsmanship is still valued.

The machines are designed to execute large-scale production, and the work is carried out by people with a lot of experience and love for their profession. There are also sustainability issues in the brick industry.

For example, producing a stone requires a lot of energy, but on the other hand the product lasts a very long time. It is an industry that thinks about the long term, but also must keep up with new developments.

By replacing regular industrial clays with PFAS-contaminated clay soil, we have a win-win situation. We create an application for a significant residual flow, clean up the PFAS from our environment and give the brick industry the opportunity to produce a very sustainable product.

However, I ran into an issue; where do you start in the chain? Because the brick industry is not the 'problem owner' and it is also not solely responsible for the solution.

You're saying the brick industry doesn't ‘own’ the problem. Who does, which parties need to be brought together?

The parties with a real problem are the landowners with clay soil contaminated with PFAS. The majority of PFAS chemicals in our environment are released during industrial production and the use of PFAS agents such as firefighting foam. That could be practically anywhere. At this stage, it only becomes an active problem when the ground needs to be dug, or when the levels of PFAS are so high that they seep into the surrounding area. The clay soil that is cleared during these types of clean-ups currently has no purpose or destination. The only option is to store it in a depot. Which obviously is not a solution, it just disappears. So now with Claybens I am attempting to connect these 'problem owners' with the brick industry.

How are you going to convince these landowners and brick producers, where in lies the power of Claybens?

I think it is very important that the bricks we produce are functional. There is so much PFAS captured in clay soils globally and my goal is to eliminate those chemicals completely. That is only possible if you think big. That is why I consciously chose not to redesign the brick itself. I want my bricks to be produced as quickly and as easily as possible within the existing industrial process. And that construction companies, contractors and architects do not have to adapt their ways of working to integrate my brick versus a 'normal' brick. My mission is to clean up the PFAS, not to make the most beautiful brick in the Netherlands, although as a designer of course I am sometimes tempted.

So, your mission is to clean up PFAS-contaminated soil by turning it into bricks on a large scale. But making a 100% sustainable product is often difficult in practice. What dilemmas do you face?

I have been working on Claybens for three years now. Sometimes progress is slow because each step must be taken with care and consideration. The solution I offer is sustainable, but the raw material I work with is not at all. Whenever you enter a terrain with a lot of contaminated soil, you receive official instructions: you’re not allowed to sit on the ground, or eat anything that comes out of the ground, you can’t eat the leaves, or drink water from the streams. That always serves as a good reminder that this is a dangerous substance.

Working with heavy toxins requires caution, you must take all the correct steps. In addition, baking bricks on an industrial scale is a major process, where incorporating a new source material can be quite an undertaking. Sometimes it can be difficult to oversee this process, which is why I divide the total process into separate steps, based on the Technical Readiness Levels. By working from level to level I keep things manageable for myself, and we are continuously ensuring the quality.

You are making significant progress. What stage of development is Claybens in currently? Is the product already commercially viable and available on the market?

Our next step is moving from lab scale to practical scale, in collaboration with a brick manufacturer. The bricks are not yet available on the market, but we are working hard to make this happen. We have achieved good results in the lab, and we also expect success on an industrial scale, but the proof is in the pudding. We bake bricks which we then grind down to test them for PFAS, where we also measure the flue gases. There are currently two pilot projects active where we’re performing these tests on different types of clay soil.

The product is out of the lab, and you have test projects up and running. What future do you see ahead of you?

Large-scale tests are planned for next year. We want to bake 50,000 bricks, which is approximately the amount needed for a terraced house. I am very curious to see the results. When this phase is also completed successfully, we will be ready to set up the production lines and start working on certification. We can then start with a first real full-scale location, where we can convert their PFAS-contaminated clay soil into a usable and clean product.

Let's together turn PFAS-contaminated soils from a burden into a resource and use it to build beautiful houses!

What is the most important message you want to put out into the world?

PFAS is a collection of toxic chemicals that we will have to tackle sooner or later. The awareness about this is growing, almost every day you can read something in the news about PFAS. Using the principles of design, I have developed a solution that makes the decontamination of PFAS-contaminated clay soil possible, by connecting the soil and brick industries. But moving from design and testing to the real world requires a united effort. From the soil, construction, and brick industries, but also from the government. Let's together turn PFAS-contaminated soils from a burden into a resource and use it to build beautiful houses!

Instagram: @emy_bensdorp