Design Dilemmas

We want to make people aware of the power of good design for a sustainable future.

Secrid makes Cardwallets, but Secrid is much more than that. We also have a message to share. We want to make people aware of the power of good design for a sustainable future. It is our mission to change the focus of industry from producing more to producing better. We call that Industrial Evolution.

Let’s start with ourselves. With the launch of our Cardwallets in 2009, we changed the wallet market. Since then, we have been continuously improving our designs. For example, we do a lot of material research into leather, leather alternatives and aluminium.

We discussed this material research with colleagues Sam Smeets (sustainability), Danielle van Geer (collection) and Bente Arts (business development). They talk openly about the choices and dilemmas that come with developing and improving a product in the most sustainable way possible.

At Secrid we believe in design as a force for good. Can you explain?

Sam: At Secrid there is a lot of room to innovate, to improve on existing designs. Some design companies employ as many as 40 marketeers and PR people. In contrast, we have about 40 people working on product development. They are continuously improving and innovating our designs, with people and planet in mind.

For example, over the past year we have made significant progress with aluminium. And we’re investigating new materials to replace bovine leather. We keep tabs on all new developments, with a preference for organic and circular materials. We test them thoroughly, and where possible we introduce these materials into our collection.

Danielle: But we don't just follow trends unquestioningly. We weigh the pros and cons very carefully. For example, many leather alternatives don’t work how we need them to in practice. Often natural materials are mixed with glue and plastic, which means they can’t be recycled, or the wallet’s lifespan is very short when used intensively. Even when these kinds of trends become popular, we don’t always consider them as good options. Because we take a holistic view, we are always very critical about which developments really make a difference. We carefully consider the nuances.

A holistic view. What does that mean?

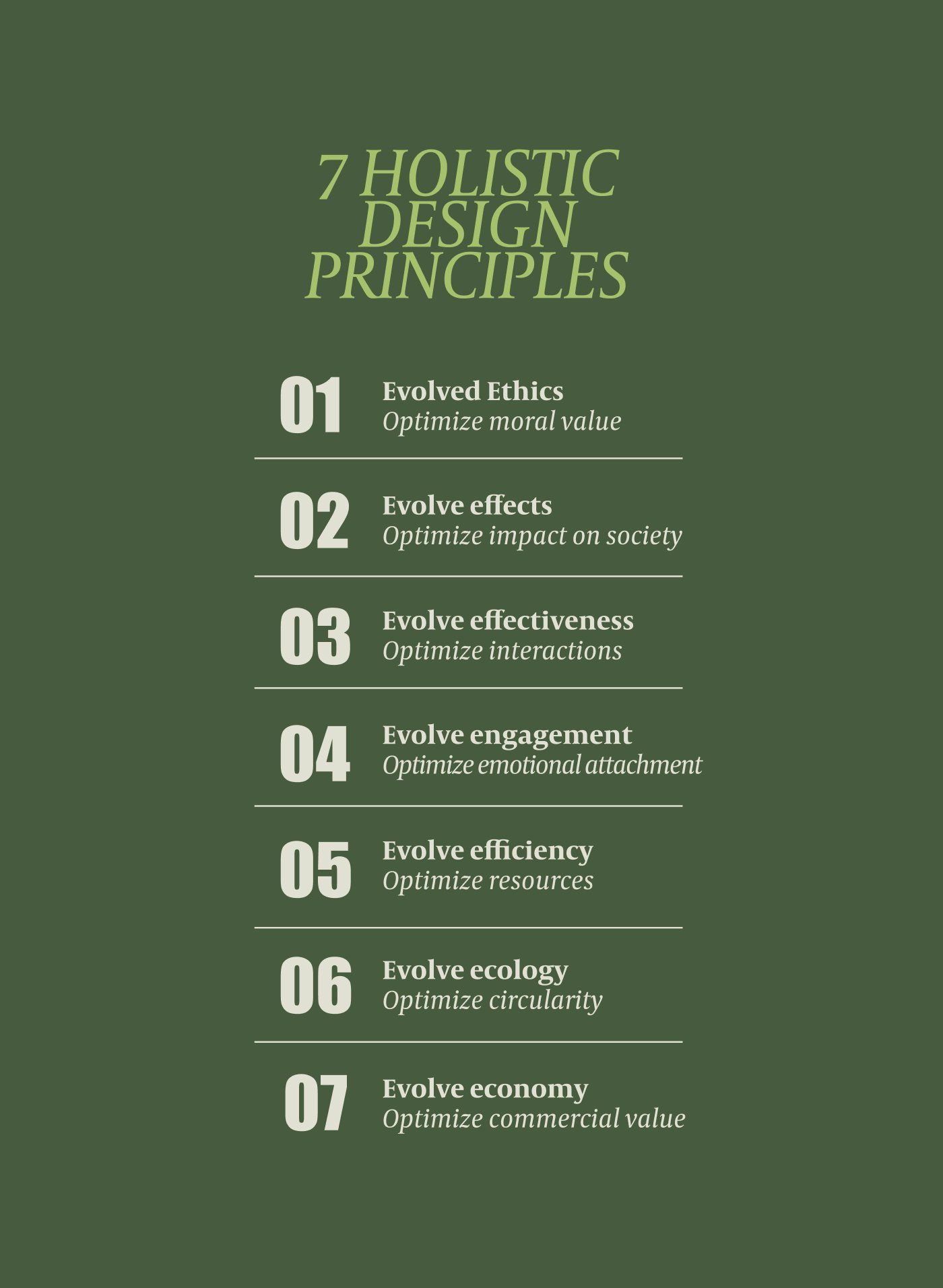

Sam: Over the past thirty years, Secrid's working method has led to a unique design philosophy based on 7 holistic principles. That’s a number that often pops up at Secrid. These principles ensure that we look at a design from different angles, to make better choices.

Often these choices are about, for example, the circularity of a material and the lifespan of a product. A material may be slightly more sustainable in terms of the raw material, but we don’t want the consumer to end up with a worn or defect product after two years. That way we are just contributing to the waste mountain.

Bente: We also look at commercial, emotional, functional, social, and ethical aspects. The product must always improve on something, have a positive social and environmental impact, but it must also be functional and aesthetic. It must make sense on every level, otherwise it’s not a Secrid product.

Danielle: Our holistic way of working also provides insight into the dilemmas associated with each design choice. It makes us more aware of the effect one choice has on the next. For example, we want to employ people who are disadvantaged in the labour market, which is also more expensive. Yet that is what we choose to do.

Is the use of leather a good example of a sustainability dilemma?

Danielle: Yes, leather is a good example. In the Secrid kitchen, vegetarian meals are consciously prepared every day, because we believe that we should use less animal products. But we still use bovine leather, because so far, we find it more sustainable than most alternatives.

Sam: Bovine or bovine leather is strong, has a long lifespan and becomes more beautiful over time. We also see bovine leather as an upcycled material. As long as people eat dairy and meat products, and that demand exceeds the demand for leather, there will be hides available for us to use. But it is a dilemma for us, so we are always looking into natural alternatives.

We think it’s important to involve consumers, and other designers, in these dilemmas, and to provide insight into our choices. We invite them to join the conversation because we cannot solve it all alone.

We see bovine leather as an upcycled material.

You conduct a lot of research into more sustainable materials. What do these investigations look like, what is important?

Sam: We start by finding out what is already known about a new material. We look at how transparent the supplier is, where the production locations are, whether renewable energy sources are used and how they deal with waste. If we see potential, we make a life cycle analysis in collaboration with EcoChain. In addition, we always look at the 'end of life' of the material. Can it be repaired or recycled? Can we or the supplier take the material back?

Longevity is very important to us. To be able to promise this to our consumer, we test thoroughly.

We perform tear tests, pull tests, we test the colour fastness of products with acid and water, as well as how the material ages. This way we can weigh different factors to determine the quality of the material.

We also investigate what it means to start employing a material at scale. Is choosing this material still a good decision if it is being sold in 80 countries? For example, when something can only be recycled under certain circumstances in the Netherlands, but not in the 79 other countries, we must reconsider our choice.

If a certain material is not yet suitable but shows promise in other areas, we will work with the supplier to determine what is needed to improve it. We share the data and findings from our technical tests with them, so that they can improve. Because it may not work today, but it could in six months. And that also benefits us.

Are there already materials being used instead of bovine leather?

Danielle: This year we added Mirum to our collection. Mirum is a young company that develop an organic material that meets all our requirements. Mirum is a completely natural product, based on FSC-certified natural rubber, agricultural waste, and minerals. The production of Mirum has a significantly lower CO2 footprint than bovine leather. The Mirum material is pressed onto a woven cotton carrier, without the use of glue. This is the best plant-based leather alternative we've found so far.

We also have several plastic alternatives in our collection. After two years of testing with different plastics, we discovered that TPU (Thermoplastic polyurethane) meets our sustainability requirements. The high-frequency welding of TPU reduces the number of steps in the production process. This results in a strong and seamless connection of the material. It still needs a backing, which means it is not yet recyclable. We have been manufacturing this vegan wallet since 2022. We have not yet been able to determine its true lifespan with daily use, because this is a new material for our wallets.

Liba is a material that consists of 30% recycled TPU. It’s a mono-material and therefore recyclable. This is the next innovative step towards circular product design, which uses existing materials to extend their lifespan instead of new resources.

Another collaboration is with the Swiss brand Freitag, who are specialists in upcycling discarded truck tarpaulins. This waste material is strong and ages beautifully, just like leather, making it suitable for our products. We would never use this PVC-based material if it were new, but upcycling this waste stream is a perfect solution.

You have introduced several alternative materials into your collection, such as Mirum and TPU. What are the main problems you encounter with other alternatives?

Danielle: In the past we introduced recycled leather and Jacquard into the collection, but we’ve since retracted both materials. When leather hides are cut, that results in lots of scraps, which are too small for use in production. Shredding these scraps of leather and mixing them with latex, results in a lovely material with good results in our laboratory tests. However, after we introduced it into our collection, the average lifespan in daily use turned out to be much shorter than that of bovine leather. We have since halted sales and are now investigating how to extend its lifespan.

We stopped using Jacquard for a different reason. Jacquard is a rich and beautiful weaving technique but evolving it from a fabric to our wallets is complex, making it too expensive and difficult to sell.

Sam: Apart from Mirum, all other experimental organic 'leathers' are still a mix of organic material and plastics. For example, we regularly see that a so-called “sustainable” leather contains only 30% of the sustainable alternative. The other 70% is glue and other binders. You see this, for example, in many materials made from fruit, such as apple and mango peels. And even with natural materials such as cork, bamboo, linen and mycelium, synthetic additives are needed to make them strong enough to use in our product. As a result, we don’t consider them suitable options yet.

Another way to create leather is using fish skins. Salmon skins, for example, have always been considered a waste material. In recent years, several companies have started investigating how to turn this waste stream into leather. Fish skins, like bovine leather, have an attractive look and long durability. But because fish skins are much smaller, turning them into products is a more delicate process. You can only use them in production at a high luxury price point. We like that this solution utilizes a waste product, but salmon farming is of course still part of the bio-industry.

Leather also needs to be processed before you can use it for products, do you consider that?

Bente: These operations are often chemical processes, which can be accompanied by a lot of water consumption and pollution of the environment. Because Secrid consciously chooses partners close to home, instead of in Asia, we know that their operations are clean and efficient. In tandem, we are investigating the possibilities of transitioning to a biodegradable process.

In that regard we are collaborating with DesertSpring to employ an innovative leather tanning technique that uses the leaves of the sea buckthorn plant. Their approach is free of chlorine and metals and therefore ensures clean wastewater. In addition, sea buckthorn helps prevent soil erosion, captures CO2 and fixes nitrogen in the soil. It also provides social benefits to local communities where the plant grows. DesertSpring is still in the start-up phase and cannot yet deliver this technology at scale at a feasible cost.

We also work with designers experimenting with natural dyeing techniques. Fabulous Fungi dyes leather with colour pigments from fungi. And llfa Siebenhaar has developed a technique for dyeing materials with bacteria. Both still have a way to go before they can deliver at a commercial scale, but they represent interesting developments that we are following. For example, we want to further investigate and test whether we can consistently create the same colours with a natural dyeing process. An important consideration is how consumers will respond to these 'imperfections'. Perhaps it will add value, because the result is always slightly different and so every consumer has a unique item.

We hope to inspire consumers, designers & others to consume and produce better, instead of more.

Are you also looking into other materials, you mentioned aluminium earlier?

Sam: Our product consists of 3 important material flows: leather, aluminium, and plastic. Based on a life cycle analysis of our wallets, we discovered that most of our environmental impact is with aluminium, as the CO2 impact of this material is the highest.

Over the past two years, we have researched how we can switch from primary aluminium to recycled aluminium together with our suppliers. By using a recycled material, you can skip many steps in the production process, including those with the highest energy intensity. This has led to a CO2 reduction of 27% per wallet we produce. This is one of the biggest steps we have taken in the last ten years.

How do you see the future of Secrid?

Sam: We will continue our efforts to switch to as many renewable raw materials as possible and further reduce our environmental impact. Traceability is an important part of this. And we want to make it very easy for consumers to extend the lifespan of our products, for example through repair services, sharing platforms and recycling options.

Danielle: We are also working to establish a strong brand. Many people know our product, but as a consumer you do not immediately see that we believe in design as a force for good. They often don’t know about our mission, that we want to drive the Industrial Evolution.

Bente: In the future, we want to involve consumers more in our sustainability vision and our holistic design philosophy. We hope that we can inspire consumers, designers, and other companies to consume and produce better, instead of more.

Kurzgeschichten

Secrid Talent Podium - Sumo Baby

Luisa Kahlfeldt markets a high-performance diaper that reduces a baby's diaper use from about 5,000 to 25 diapers.

Secrid Talent Podium - ClimaFibre

Sunflowers can help to reduce our dependence and the environmental damage of cotton in the fashion industry.

Secrid Talent Podium - Super Local

Luc van Hoeckel designs solutions for the 90% of the world's population without access to decent basic facilities.

Secrid Talent Podium - Vorkoster

To combat food waste, Kimia Amir-Moazmi is working on a product that allows consumers to see for themselves whether food is still safe to eat.

Secrid Talent Podium - Solarix

Solarix designs and produces aesthetic solar panels as façade cladding.

Secrid Talent Podium - Claybens

Emy Bensdorp is developing a technique to transform clay soil contaminated by PFAS into 100% clean bricks.